TabCN-35-37-41C Tablet Press

The machine is a double-pressing automatically revolving piece-pressing machine which could make grain be pressed to be round piece ,be carved characters ,special shapes and double color piece prescription .It is mainly used in manufacturing piece prescription for pharmaceutical industry enterprises like chemical industry ,foods, electronics .

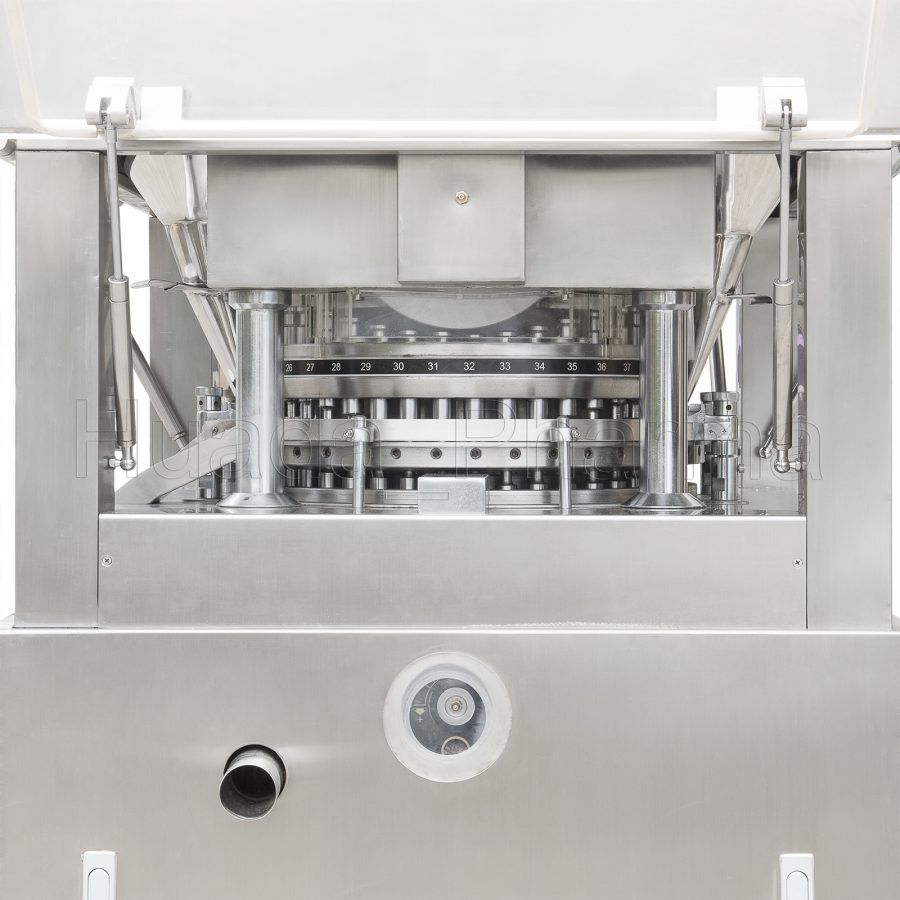

Tablet Press TabCN-35-37-41C

The machine is a double-pressing automatically revolving piece-pressing machine which could make grain be pressed to be round piece ,be carved characters ,special shapes and double color piece prescription .It is mainly used in manufacturing piece prescription for pharmaceutical industry enterprises like chemical industry ,foods, electronics .

- The machine is fully-enclosed, made of stainless steel, meet the G.M.P requirement.

- It has transparent windows so that press condition can be observed clearly and the windows can be opened.

- Cleaning and maintenance is easier.

- The machine can press not only round tablets but also different geometrical shape tablets, annular tablets, and the tablets may have the impressed letters on both sides. A power suction unit is attached to take the residual powder during operation so that the blockage powder can be collected and be reused.

- An overload protection unit is included in the system to avoid the damage of the punches and apparatus.

- The machine’s worm gear drive adopts fully-enclosed oil-immersed lubrication with long service-life, preventing cross pollution.

- The speed is stepless speed regulation, which can be adjusted at will.

- Realization of electromechanical integration, using touch screen PLC control and operation.

Rotary tablet press advantages:

- Guarantees a higher output as high production levels can be achieved with a minimal amount of labor.

- higher output speed.

- It reduces wastage of material.

- It allows independent control of both the weight and hardness of tablets.

Main application:This machine is a doule-press type, continuous automatic tablet press for pressing granular raw materials into tablets. It is mainly used in pharmaceutical industry and also the chemical, food, electronic, plastic and metallurgical industries.

Detail Images

|

|

|

|

| Peripheral Cover The peripheral cover is fully-sealed and made of Auce stainless.easy to clean without dirty corner. |

Structure Of Rotary Table The rotary table is a main component which consists of upper/lower bearings and main shaft. |

Structure Of Rail The rail is cylinder cam and plane concaved wheel consisting of upper/lower rail,as well as The track of movement of upper/lower impact lever. |

Filling-Adjustment Unit The filling adjustment unit is designed for adjusting the weight of tablets. |

|

|

|

|

| Tablet-Thickness Adjustment Unit This unit is designed for adjusting the thickness of tablet. |

Feed Unit Feed unit consists of feeder,bucket rack,column,adjustable screw and bucket. |

Outlet | Drive Components |

| Model | TabCN-35C | TabCN-37C | TabCN-41C | |||

| Punch quantity | 35 set | 37 set | 43 set | |||

| Max. tablet pressure | 80 kN | |||||

| Max. filling depth | 15 mm | |||||

| Max. tablet diameter | 13 mm | |||||

| Max. tablet thickness | 6 mm | |||||

| Production capacity (pc/h) | 150000 | 160000 | 170000 | |||

| Turntable speed | 14-37 r/min | |||||

| Motor power | 4 kW | |||||

| Machine weight | 1700 kg | |||||

| Dimensions | 950*1230*1670 mm | |||||

CapsulCN DZ Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Contact CapsulCN DZ

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

Constantine, 25000, ALGERIA

+213-555-27-33-05

dz@capsulcn.com