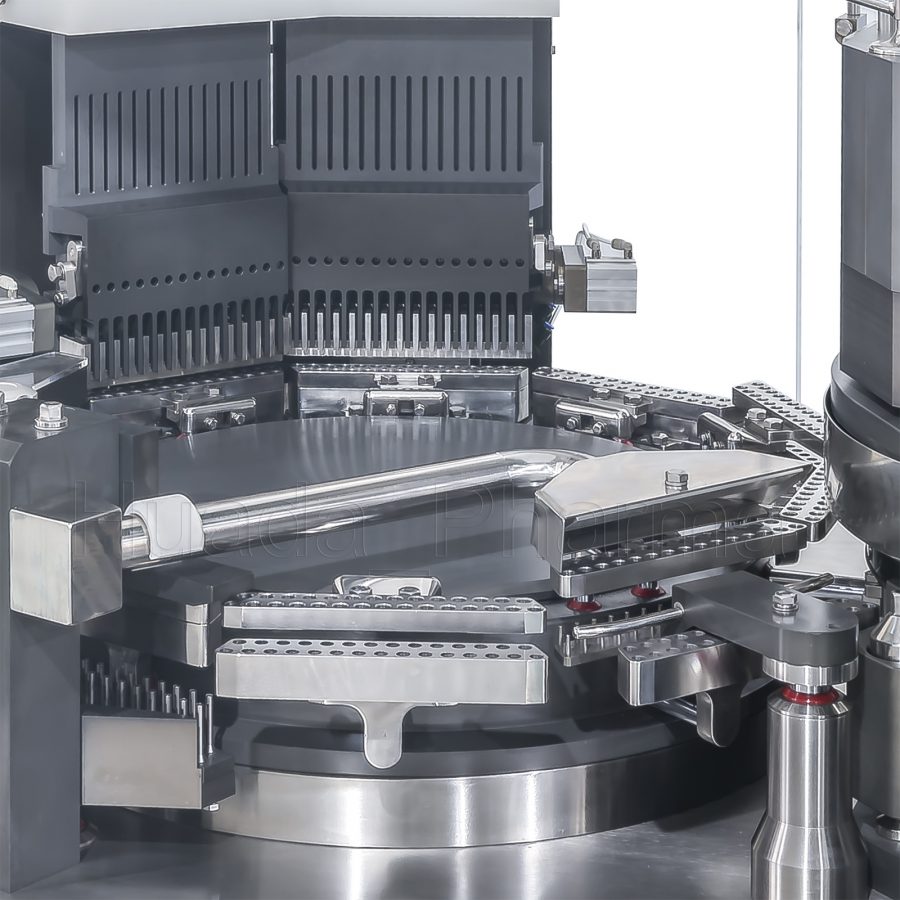

CapCN-72/240 Capsule Filling Machine

CapCN-72/240 automatic capsule filler processes the products for optimal productivity up to 1200/4000 capsules per minutes, featuring low-maintenance operation, minimal downtime, and overall dependable production.

Fully Automatic Capsule Filling Machine CapCN-72/240

CapCN-72/240 automatic capsule filler processes the products for optimal productivity up to 1200/4000 capsules per minutes, featuring low-maintenance operation, minimal downtime, and overall dependable production.

Powder dosing uses the 5 stage tamping technology for an enhanced accuracy. Filling of pellets is available.

Capsules from the bunker are fed into the orienting device along the vertical guide.

Then they are transferred into special cells on the rotor. Here the capsule is separated, after what the bottom part comes to the filling position.

After filling the bottom part with the material, on next positions the non-separated capsules are rejected, and the filled bottom parts are joined with top parts, counted and taken away into the receiving box.

The benefits that you will enjoy from using the automatic capsule filler machine include:

- The machines are simple and easy to operate, clean and maintain at very low costs.

- It has adjustable and flexible settings that will improve the levels of capsule filling and production.

- Most parts of the machine are enclosed tightly thus preventing the entry of dust and other foreign materials.

- Since the filling process is automatic, the machine saves time and energy through a fast filling process.

- The machine also comes with automatic sensors that will warn you of any imminent danger in the machine operations.

- The sensors will also assist in the predetermination of the filling levels in different hoppers.

- It has different parts that will maintain the integrity of the capsules leading to minimal or no damages on capsules.

- The filling process is precise and accurate leading to proper filling levels of all the capsules.

- You can easily integrate the machine properly with other machines for a complete encapsulation process.

- The machine is also compliant to the right quality standards such as CE and cGMP that ensures high quality standards.

Remarks

- Powder filling system is very high filling accuracy.

- The fully enclosed design of the split and capsule feeding system prevents capsules which fall into the capsule transfer chamber inappropriately and ensures smooth operation of the capsule.

- The capsule-type injection system effectively protects the filled capsules from breaking by the machine.

- And ultra-precision integrated rotary table has a similar small size, light weight load, long life, three years of free oil maintenance and so on.

| Model | CapCN-72 | CapCN-240 | |

| Max capacity | 72,000capsules/hour | 240,000capsules/hour | |

| Suit for capsule size | 00#~5# | ||

| No. of Mould Bores | 9 | 29 | |

| Power | 380/220V,50/60Hz,7kW | 380/220V,50/60Hz,12kW | |

| Noise | <70dB | <70dB | |

| Machine dimensions | 980x980x2100mm | 1950x260x380mm | |

| Net weight | 1,000kg | 2,800kg | |

| Powder filling system | ✔ | ✔ | |

| The capsule-type injection system | ✔ | ✔ | |

| Light weight load | ✔ | ✔ | |

✔: Yes 🔘: Optional

CapsulCN DZ Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Contact CapsulCN DZ

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

Constantine, 25000, ALGERIA

+213-555-27-33-05

dz@capsulcn.com